January 27, 2023

Incremental Cost: Step by Step: Incremental Costs in the Shadow of Irrelevant Costs

From the perspective of a financial analyst, incremental costs are crucial for conducting break-even analysis and forecasting future expenses. A production manager, on the other hand, might view these costs as a guide to optimize production processes and resource allocation. Meanwhile, Budgeting for Nonprofits a strategic planner would consider incremental costs when evaluating the potential of entering new markets or launching new products. Incremental costs are a vital component of financial analysis and strategic planning. They provide a granular view of the cost structure, enabling businesses to make informed decisions that align with their financial goals. Understanding and effectively managing incremental costs can lead to improved profitability and long-term success.

- Applying the formula, the Incremental Cost is $70,000 minus $50,000, equaling $20,000.

- By analyzing the incremental cost, businesses can make informed decisions about pricing strategies, resource allocation, and overall profitability.

- Unlike fixed costs, which remain constant regardless of output, incremental costs vary with production volume, making them a key factor in pricing decisions.

- Some custom products might not be readily available for the business to buy, so the business has to go through the process of custom ordering it or making it.

- When making short-term decisions or selecting between two possibilities, such as whether to accept a special order, incremental costs are important.

- From the above information, we see that the incremental cost of manufacturing the additional 2,000 units (10,000 vs. 8,000) is $40,000 ($360,000 vs. $320,000).

Methods for Calculating Incremental Cost

In these industries, the gap between average costs is particularly large, making incremental analysis even more valuable for strategic decisions. When a manufacturing company decides to increase production to produce extra units, numerous incremental costs come into play. Consider a furniture manufacturer that currently produces 1,000 wooden chairs monthly and plans to increase production to 1,200 chairs. The incremental costs would include additional wood, hardware, glue, and finishing materials needed for those extra 200 chairs, which contribute to the overall cost per unit . Labor costs might increase if more worker hours are required for assembly and finishing. According to research by McKinsey, companies that excel at resource allocation deliver 30% higher returns to shareholders than their less skilled peers.

Step 3: Define the Incremental Volume Change

- This could mean more deliveries from vendors or even more training costs for employees.

- These costs can include direct materials, labor, or overhead expenses that will be affected based on various factors such as changes in production levels or sourcing options.

- Analyzing incremental costs in different scenarios is essential for businesses to make informed decisions.

- This expense includes costs such as labor fees, supervision expenses, and related taxes.

- It includes the cost of labor, raw materials, energy, transport, administrative, and marketing expenses for producing an additional unit.

While incremental costing is a valuable tool for estimating additional costs, it is crucial to be aware of its limitations and considerations. By acknowledging these factors and incorporating them into the cost analysis, businesses can make more informed decisions and improve the accuracy of their cost estimations. By analyzing them thoughtfully, businesses can make informed decisions and optimize their operations. According to a study by Forbes Magazine, companies that regularly invest in updated technology see significant increases in bookkeeping productivity and revenue over time. Therefore, despite the initial incremental costs, investing in new equipment can be a smart financial decision for businesses looking to grow and improve their operations.

- This approach involves comparing the costs of two or more alternatives to determine the difference in expenses.

- From a business standpoint, incremental cost can be used to determine the profitability of a new product or service.

- These costs are vital for decision-making, especially when a company is considering scaling up its activities or introducing new product lines.

- This may require a contract analysis to track and record costs that were previously expensed.

- Although a portion of fixed costs can increase as production increases, the cost per unit usually declines, as the company isn’t incurring additional fixed costs to produce the added volume.

I Want To Be A Lawyer: A Step-By-Step Guide to Becoming an Attorney

These can include research and development, manufacturing systems, distribution channels, marketing campaigns and product testing. In this article, you will find an easy to follow definition, a step-by-step guide to calculate incremental cost, and real-world examples to help you apply the concept in your business. Manufactures look at incremental costs when deciding to produce another product. Often times new products can use the same assembly lines and raw materials as currently produced products. Unfortunately, most of the time when manufacturers take on new product lines there are additional costs to manufacture these products.

The first commission of $5,000 is amortized over six years, and the $3,500 commission is amortized over the last three years under the renewal contract period. Technology Company A incurred the following costs to obtain a three-year contract with Customer B. Company A expects to recover all the costs incurred to obtain the contract. Cash flow analysis in sales is the backbone of any business’s financial health. Sensitivity Analysis is a powerful technique used to evaluate how sensitive a model or system is to changes in its parameters. It allows us to explore the effects of small perturbations in input variables on the overall outcome.

In general, the fuel cost Fi for a plant, is approximated as a quadratic function of the generated output PGi. Company A should only capitalize the $5,000 commission paid to its salesperson. The costs related to the delivery of the bid on the contract do not qualify because those costs would have been incurred even if the company did not ultimately obtain the contract. Company A should amortize the recognized asset over the three-year contract term. Analysis of incremental costs under ASC 606, including identifying the incremental costs, the criteria for capitalization, and how to amortize these costs.

- These costs are generally composed of variable expenses, such as direct materials and direct labor, which fluctuate directly with production volume.

- This principle forms the basis of cost-volume-profit analysis, one of the most practical tools in management accounting.

- No complex theories—just practical steps that work whether you’re running a coffee shop or managing a manufacturing plant.

- Many companies use stopwatches or specialized software to track how long each production step takes.

- As a result, the total incremental cost to produce the additional 2,000 units is $30,000 or ($330,000 – $300,000).

The calculation of incremental cost shows a change in costs as production expands. While most incremental costs are variable costs, the two terms are not synonymous. Incremental costs include all expenses, both variable and new fixed, that result from a specific decision. These costs are generally composed of variable expenses, such as direct materials and direct labor, which fluctuate directly with production volume. Incremental cost also includes any new fixed costs specifically triggered by the expansion or project. For instance, leasing new specialized machinery for a new product line would create an incremental fixed cost.

Remember, incremental cost isn’t just about numbers; it’s about making smarter decisions. In summary, incremental cost analysis empowers decision-makers to weigh incremental fees the benefits against the additional expenses. By considering both short-term and long-term implications, organizations can make strategic choices that align with their goals and resources.

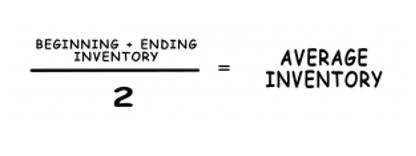

To calculate incremental cost, companies compare the cost of producing the first unit with the cost of producing the additional unit. Incremental cost refers to the additional cost incurred by a company when producing an additional unit of a product or service. In other words, it is the cost increment that occurs when the level of production or sale of a product increases.